|

Machine Features:

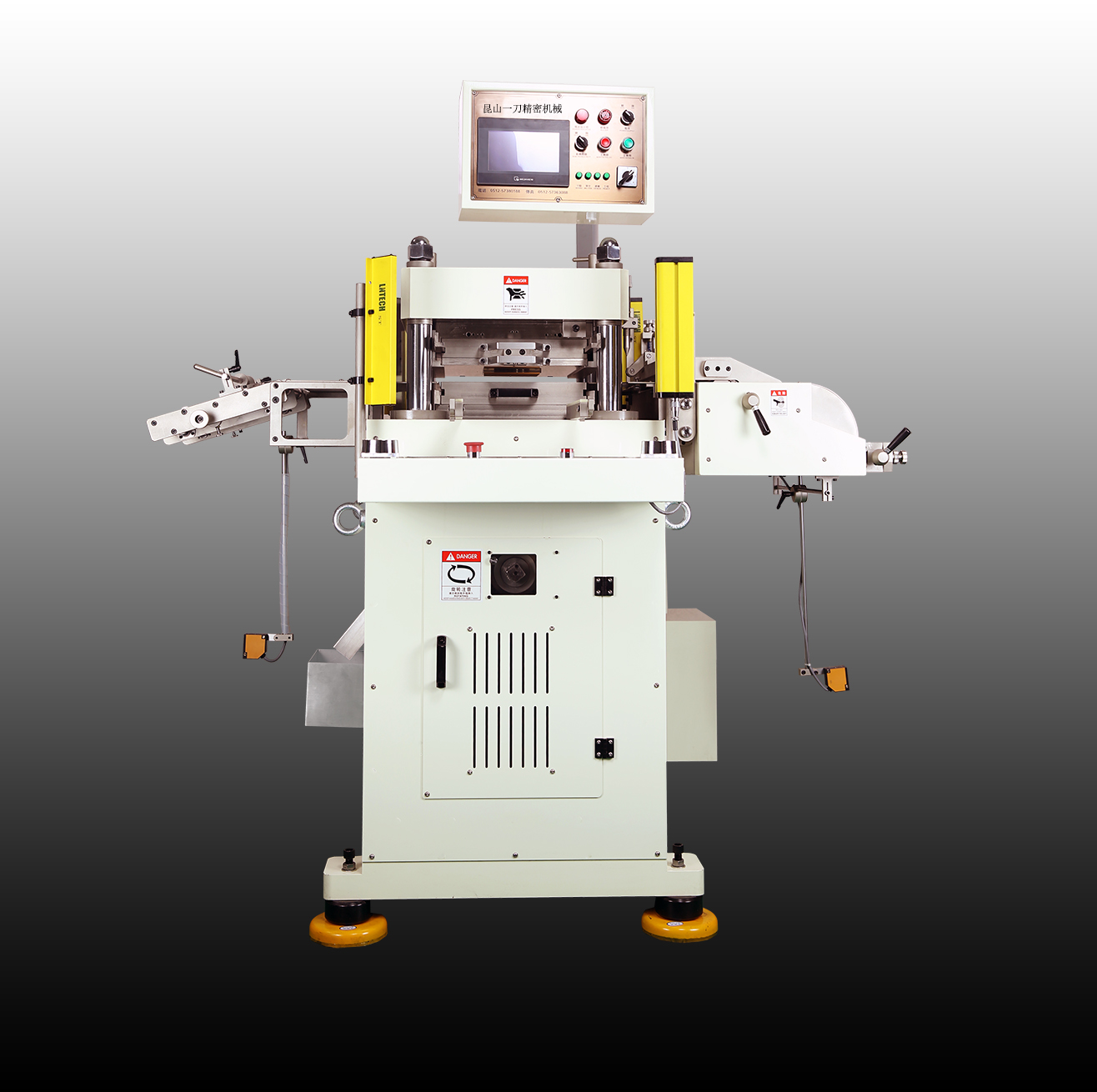

Simple, durable, high-precision, easy operating, safe and reliable performance;

1. Reasonable structure, dependable materials

A. For casting materials, using high standards of ductile iron is twice as gray

iron in tensile strength. Furthermore, casting the whole machine will make it

work stable and durable;

B. Using ball joint, eccentric wheel and Japan-based bearing and pressure

springs in the inner part of machine help it get a stable and reliable pressure

in cutting depth;

C. The template of upper & lower die cutter can be use in the same model machine,

which help operator take full advantage of them.

2. High precision

A. Blanking pressure accuracy is up to 0.003mm. Through using the touch

screen to adjust the pressure, keep touching the increase or decrease key to speed up the adjustment speed;

B. Accuracy of the material feeding is ± 0.05mm; Punching accuracy is ±

0.03mm;

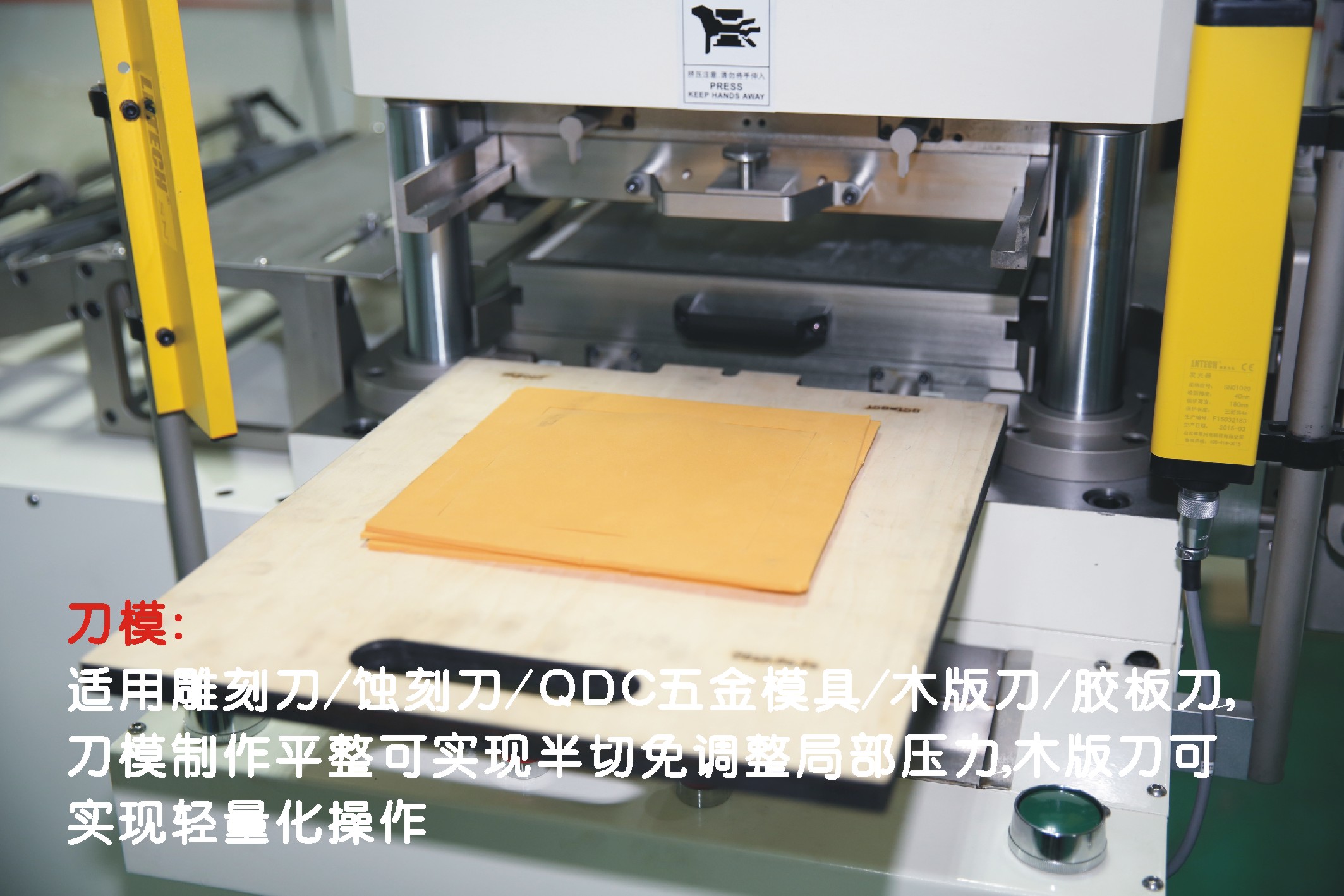

C. The thickness error of upper & lower die cutter is ±0.02mm. Means the

machine pressure is flat, operators no need to adjust partial pressure when

they request the machine cut the upper materials and keep the lower one in

good state;

3. Maximum blanking force

The punching force is up to 12 tons by using high-power & large speed reducing ratio gear motor;

4. High speed

The fastest speed of the host machine is 180 times per minute. In term of the programming, the hops in distance match automatically with materials feeding, which provide convenience for new user. Also, operator can set up the time and speed of material-pulling including the position of stopping to achieve efficient production.

5. High automation

A. Regulator system adopts touch screen digital control. it is convenient and

quick for operators to directly input digital for the pressure amount of cutting

die; Digital control of touch screen in voltage regulating system helps

operator directly input the pressure of die cutter.

B. Advanced intelligent system, simple and clear in interface.

C. High degree of safety, optical safety sensor and safe doors are provided on

each nip point. Once shielding each sensor, the machine will shut down

immediately.

D. Operator needs to press the run button both to open machine: to prevent

misuse and protect the safety of operators;

E. When the safe gate is still open, the machine cannot open for protecting the

machine;

F. The system contains fault display page, to show the fault diagnose and fault

elimination function.

6.Diversity

A. Can use woodcut knife, plastic-cut knife, graver, etching knife, QDC metal

mold and so on;

B. The hardware mold of standardization installation, fast adjustment;

C. Easy to realize automatic multiple punching;

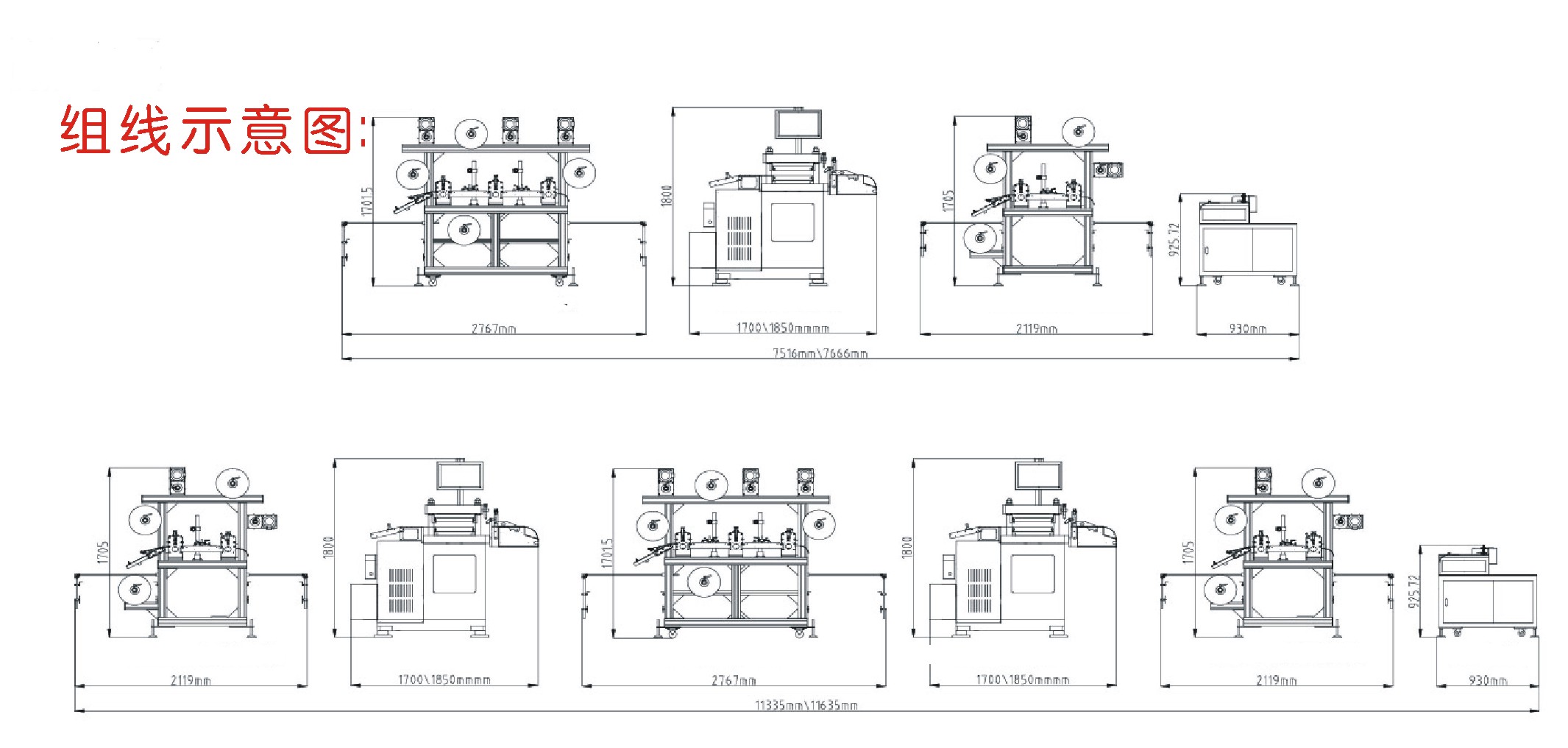

D. Can be combined randomly or fission processing line;

|

Model No.

|

220

|

350

|

420

|

|

Press Force

|

5T

|

10T

|

12T

|

|

Die Cutting Area

|

200×160mm

|

350×350mm

|

420×320mm

|

|

Maximum Material Width

|

200mm

|

350mm

|

420mm or 320

|

|

Steel Mould’s Effective size

|

170×150mm

|

300×290mm

|

370×260mm

|

|

Type of Mould

|

Woodcut knife, Plastic-cut knife, Graver, Etching knife, QDC metal mold

|

|

Shut Height of Steel Mould

|

105mm

|

115mm

|

115mm

|

|

Adjustment of depth

|

±5mm

|

±5mm

|

±5mm

|

|

Press Style

|

Jog/Discontinuous/Continuous/Engineering Pattern

|

|

Press Speed

|

300 /Min

|

180/Min

|

150/Min

|

|

Punching Process

|

24mm

|

28mm

|

28mm

|

|

Pressure Turning Way

|

Touching Screen Control

|

Touching Screen Control

|

Touching Screen Control

|

|

Materials Driven

|

Servo Motors

|

Servo Motors

|

Servo Motors

|

|

Precision of Materials Driven

|

±0.1mm

|

±0.1mm

|

±0.1mm

|

|

Punching Accuracy

|

±0.05mm

|

±0.05mm

|

±0.05mm

|

|

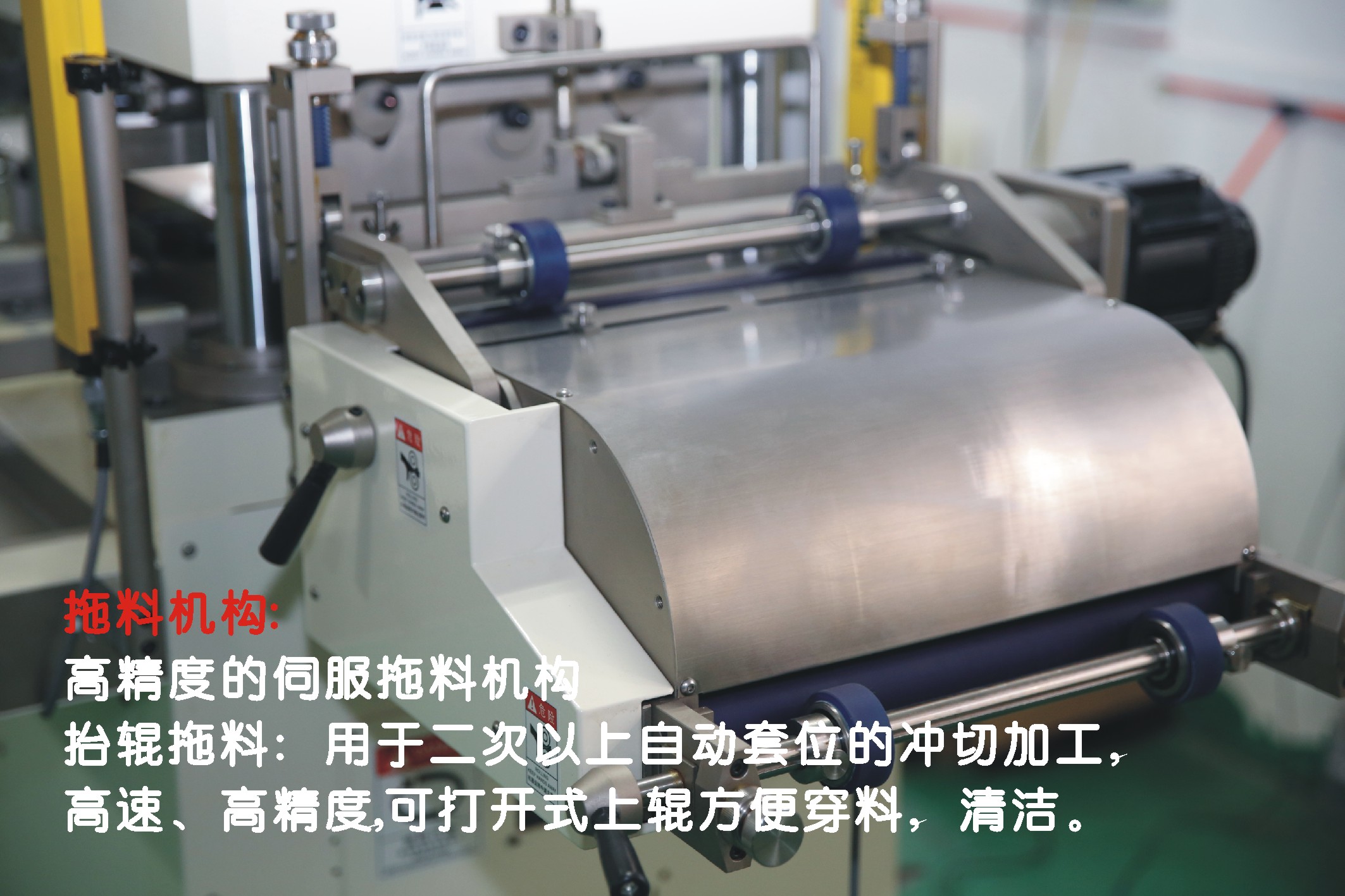

Dragging Roller

|

PU/NBR

|

PU/NBR

|

PU/NBR

|

|

Dragging Speed

|

≤50 Meter/Min

|

≤50 Meter/Min

|

≤50 Meter/Min

|

|

Potection

|

3 Optical Safety Sensors & Doors

|

3 Optical Safety Sensors & Doors

|

3 Optical Safety Sensors & Doors

|

|

Brake actuators

|

Pneumatic

|

Pneumatic

|

Pneumatic

|

|

Lubricate

|

Fully Automatic Central Lubrication System

|

Fully Automatic Central Lubrication System

|

Fully Automatic Central Lubrication System

|

|

Air Source

|

0.5-0.6mpa

|

0.5-0.6mpa

|

0.5-0.6mpa

|

|

Power Supply

|

380V 2KW

Triple Phase

|

380V 8.5KW

Triple Phase

|

380V 10KW

Triple Phase

|

|

Weight

|

1000kg

|

2000kg

|

2500kg

|

|

Machine Sizes(L*W*H)

|

1250×910×1270mm

|

1850×1150×1800mm

|

1700×1700×1700mm

|

|